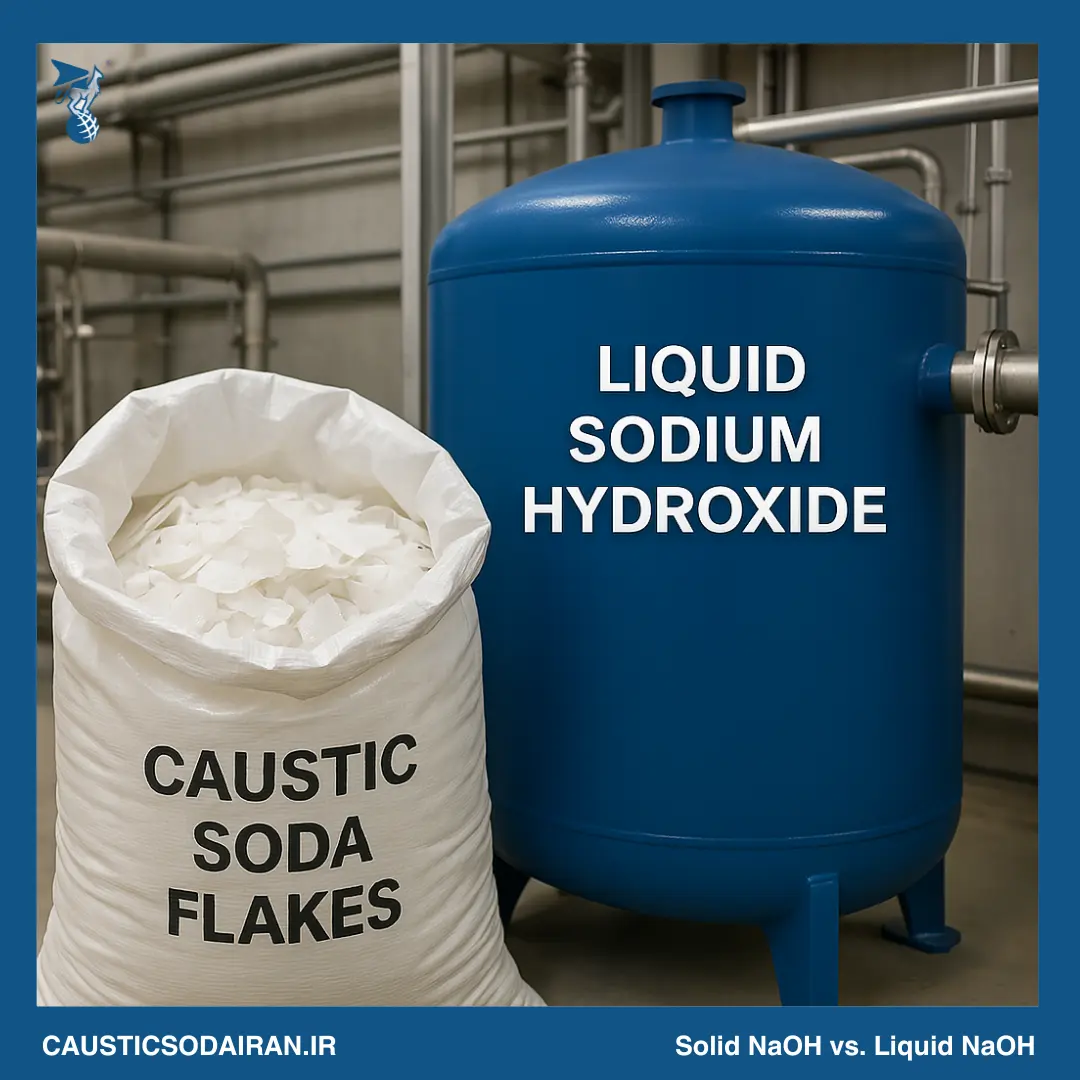

Physical State and Appearance

Caustic soda flakes are solid, opaque, and appear as dry, sharp-edged white flakes. Their solid form makes them easier to package, weigh, and store in dry environments. Liquid sodium hydroxide, on the other hand, is a transparent, syrupy solution that requires completely sealed, chemical-resistant containers to maintain stability and prevent exposure to air or moisture.

The difference in physical form affects not just appearance, but also handling, reactivity, and suitability for specific industrial processes.

Purity Levels and Chemical Concentration

Flake-form sodium hydroxide typically contains ≥98% NaOH, offering a high level of chemical purity that is ideal for applications requiring precise performance, such as in the paper and textile industries.

Liquid sodium hydroxide is usually available in concentrations ranging from 30% to 50%, diluted in water. While it may be suitable for continuous processing environments, the lower concentration may not be ideal for industries requiring high-purity raw materials.

Packaging and Transportation of Solid NaOH vs. Liquid NaOH

Caustic soda flakes are most commonly shipped in 25 kg PE-lined paper bags or in 500–1000 kg jumbo bags, with additional shrink-wrapping for moisture protection. This makes them easier to stack, store, and handle during international shipping.

Liquid sodium hydroxide is shipped in IBC tanks, HDPE drums, or stainless-steel tankers, depending on quantity and destination. These containers must meet hazardous materials shipping regulations, adding complexity and cost to international logistics.

Storage and Shelf Life

The flakes are more stable and less reactive during storage, especially when kept in dry and cool environments. They are ideal for facilities with limited infrastructure for chemical containment.

Liquid NaOH has a shorter shelf life, and over time, it can absorb carbon dioxide from the air, forming sodium carbonate and reducing purity. It also poses more risk of leakage or contamination if not stored properly.

Handling and Safety Considerations

Both forms are classified as corrosive chemicals, but the liquid form poses a higher risk of immediate skin and eye burns, especially during spills or pipe blockages. It also requires automated or closed-loop handling systems for safe use.

Caustic soda flakes are generally safer to store and handle manually, though proper PPE (gloves, goggles, face shield) is still required. The handling method should be chosen based on the facility’s equipment and employee safety standards.

Industrial Applications and Uses

Caustic soda flakes are widely used in industries where dry handling, batch processing, or export logistics are important—such as in detergent manufacturing, textile mercerization, aluminum refining, and pulp & paper.

Liquid sodium hydroxide is typically preferred in automated systems or processes where the chemical needs to be dosed continuously, such as in municipal water treatment, oil refining, or chemical synthesis in reactors.

Choosing the correct form depends on how the chemical will be applied: as a dry feedstock, or as part of a continuous dosing system.

Cost Efficiency and Logistics

Although the price per ton of liquid sodium hydroxide may appear lower, the real cost includes heavier weight, additional shipping requirements, and shorter storage life. Caustic soda flakes are more cost-efficient for long-distance transport, bulk storage, and seasonal usage.

Flakes also reduce dependency on specialized containers and are better suited for regions with limited chemical storage infrastructure.

Final Comparison of Solid NaOH vs. Liquid NaOH

| Feature | Caustic Soda Flakes | Liquid Sodium Hydroxide |

|---|---|---|

| Form | Solid flakes | Liquid solution (30–50%) |

| Purity | ≥98% | Diluted, typically 30–50% |

| Storage | Dry, stable, long-term | Sealed containers, shorter life |

| Handling | Manual or semi-automated | Closed systems required |

| Export | Easier to ship internationally | Complex shipping requirements |

| Applications | Detergents, textiles, paper | Water treatment, continuous systems |

Conclusion

The choice between caustic soda flakes and liquid sodium hydroxide depends on several factors including desired purity, application process, logistics infrastructure, and safety considerations. For industrial buyers who require high-purity sodium hydroxide, cost-effective packaging, and long-term storage, caustic soda flakes are often the preferred choice.

CausticSodaIran.ir provides ≥98% purity NaOH flakes with global export capabilities, flexible packaging, and full documentation (COA, SDS). Contact us today to discuss your specific industrial needs.

Leave a Reply