Mercerization is a chemical treatment process widely used in the textile industry to improve the physical and aesthetic properties of cotton and other cellulose-based fibers. The core chemical agent in this process is caustic soda flakes (sodium hydroxide – NaOH), which interact with cotton at the molecular level to modify fiber structure and behavior.

What Is Mercerization?

Mercerization involves treating cotton yarns or fabrics with a concentrated solution of caustic soda, typically at 20–30% concentration. This treatment causes the cotton fibers to swell, straighten, and become more uniform, which results in:

- Improved luster (shine)

- Higher tensile strength

- Better dye affinity

- Dimensional stability

The process is often carried out under tension to maintain fiber alignment and maximize surface effects.

How Caustic Soda Flakes Enhance Fiber Separation

During mercerization, the hydroxide ions from caustic soda flakes penetrate the cotton fibers and break intermolecular hydrogen bonds. This chemical action:

- Separates tightly bound cellulose chains

- Expands fiber volume

- Exposes more surface area for dye absorption

- Improves fiber uniformity and texture

The result is a smoother, shinier, and stronger cotton fabric with enhanced visual and tactile quality.

Why Use Flakes Instead of Liquid NaOH?

Caustic soda flakes are preferred in many textile operations because:

- They offer ≥98% purity, ensuring consistent process quality

- They are easy to store and transport

- They can be dissolved on-site to prepare fresh, controlled-concentration solutions

- Their solid form reduces leakage risks and handling hazards

Many textile plants prefer flakes for batch mercerization systems, especially in regions with hot climates or unstable logistics.

Common Textile Applications

Caustic soda flakes are used for mercerizing:

- Cotton yarns before weaving

- Woven cotton fabrics for higher dye depth

- Denim production (for deep indigo coloration)

- High-end home textiles and fashion fabrics

Mercerization is often combined with bleaching, dyeing, and finishing processes in integrated textile plants.

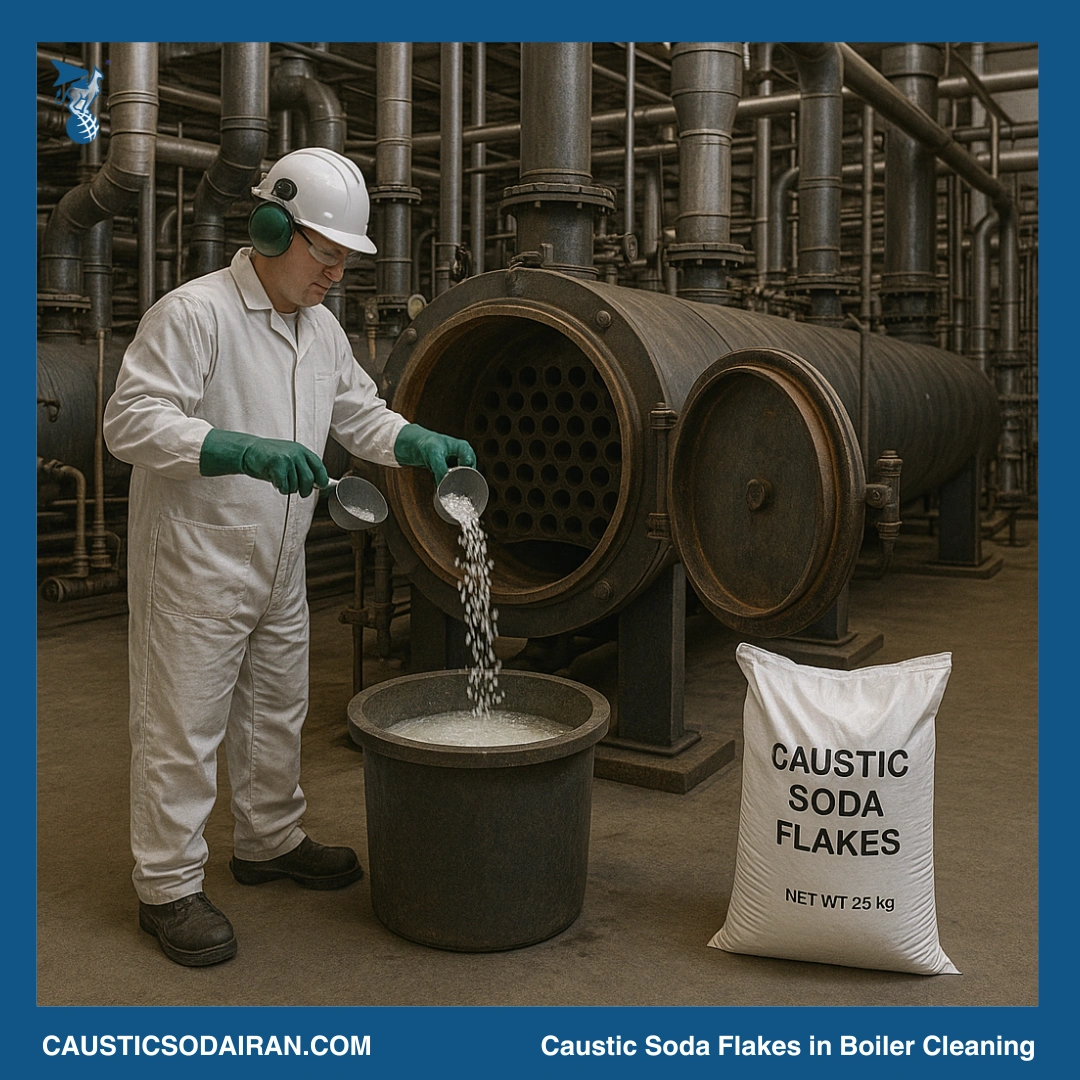

Safety Considerations

NaOH is a corrosive chemical, and textile workers should be protected with:

- Chemical-resistant gloves and aprons

- Face shields or goggles

- Ventilated processing rooms

- Neutralization tanks for waste liquor treatment

Proper training and pH monitoring equipment are essential for safe and consistent results.

Conclusion

Caustic soda flakes are an essential component in the textile mercerization process. They help enhance fiber separation, boost dyeability, and improve the overall performance of cotton fabrics. Choosing high-purity NaOH flakes ensures product consistency and process efficiency.

Iran Caustic Soda, a subsidiary of Shetab Gostar Nadin Trading Co., supplies industrial-grade flakes for textile processing worldwide with secure packaging and full export documentation.

Leave a Reply