Oil storage tanks—used for crude oil, diesel, heavy fuel oils, and lubricants—require regular cleaning to maintain operational safety and efficiency. Over time, these tanks accumulate wax deposits, sludge, tar, and acidic residues, which reduce capacity, increase corrosion risk, and contaminate future batches.

Caustic soda flakes (sodium hydroxide – NaOH) are widely used for alkaline cleaning of such tanks. With strong saponifying and degreasing power, NaOH helps break down heavy hydrocarbons and neutralize acids, allowing for easier removal of stubborn residues.

Why Using Caustic Soda Flakes in Tank Cleaning?

- Strong alkaline reactivity with petroleum sludge

- ≥98% purity, ideal for industrial-grade degreasing

- Stable storage, especially in hot or remote locations

- Cost-effective bulk cleaning solution

- Safe handling compared to some solvent-based cleaners

How It Works

When dissolved in hot water, caustic soda reacts with fats, waxes, tars, and acidic by-products, breaking them down into soap-like emulsions and soluble salts. This makes the deposits:

- Looser and easier to remove

- Less sticky and hazardous

- Flushable with pressurized water or steam

In many cases, NaOH is used alongside surfactants or degreasers for even better performance.

Typical Applications

- Crude oil tank cleaning

- Diesel and fuel oil tank maintenance

- Marine cargo hold cleaning

- Lube oil blending tanks

- Waste oil pit treatment

These procedures are often part of turnaround maintenance or pre-inspection cleaning.

Method of Using Caustic Soda Flakes in Tank Cleaning

- Dissolve flakes in water to make 5–10% NaOH solution

- Heat the solution (typically 60–90°C)

- Spray, circulate or foam inside the tank using lances or cleaning heads

- Let it soak for a specified dwell time (2–6 hours)

- Flush with high-pressure water or steam

- Neutralize the washings and handle waste properly

In some cases, closed-loop cleaning systems are used to minimize chemical exposure and waste.

Benefits

- Removes thick petroleum-based deposits

- Reduces corrosion risk by neutralizing acids

- Improves inspection visibility inside the tank

- Shortens cleaning downtime

- Minimizes need for manual scraping or entry

This makes the process safer, faster, and more cost-efficient.

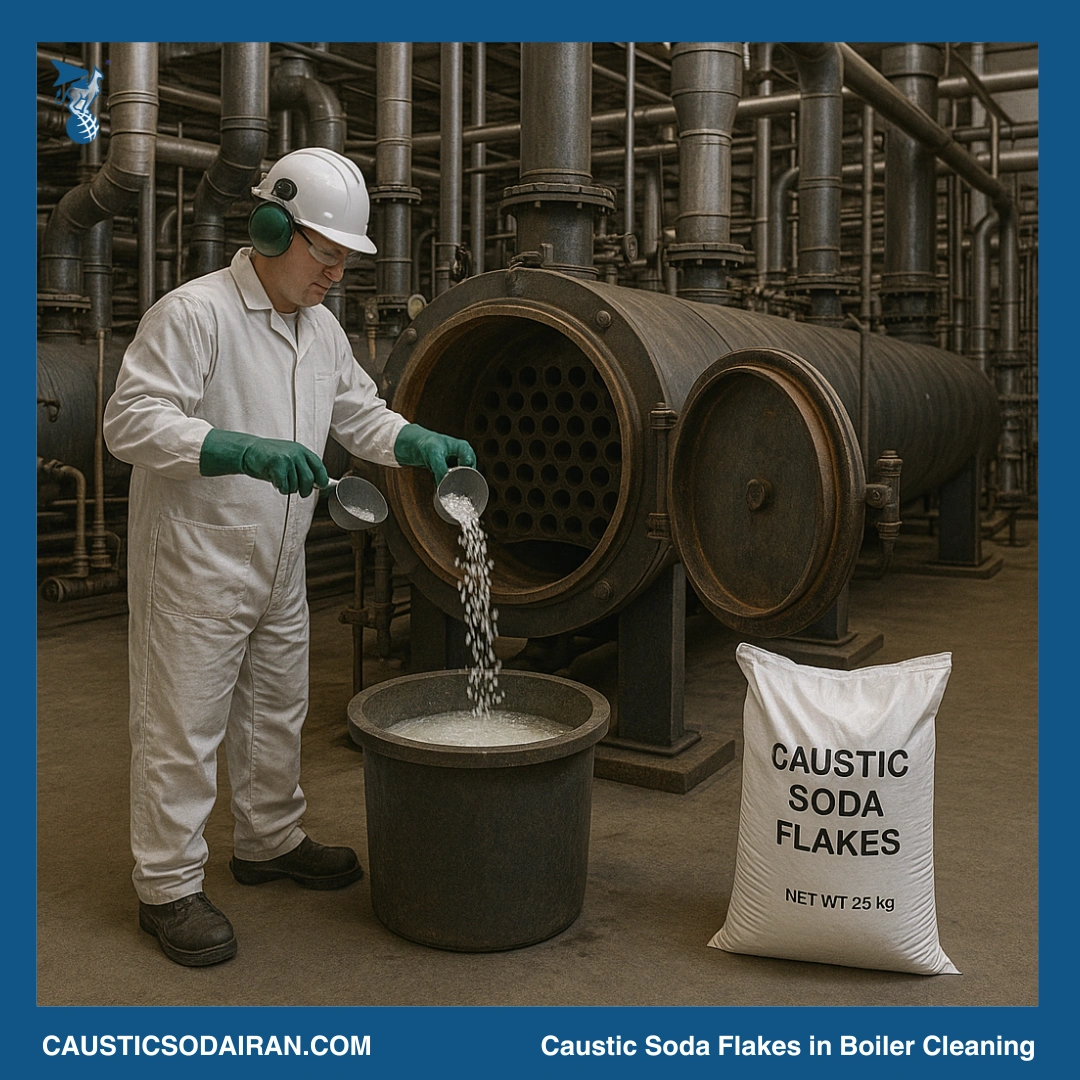

Safety and Waste Considerations

- Caustic soda must be handled with PPE and proper dilution

- Tank interiors must be well-ventilated

- Effluent must be neutralized (pH 6–9) before discharge

- Avoid use on aluminum surfaces due to corrosive reaction

Conclusion

Caustic soda flakes provide a powerful, economical, and efficient method for cleaning oil storage tanks, ensuring better hygiene, safety, and operational readiness. Their effectiveness in removing waxes, acids, and sludge makes them essential in oil and fuel management.

Iran Caustic Soda, under Shetab Gostar Nadin Trading Co., supplies high-purity NaOH flakes for industrial tank cleaning with global export services.

Leave a Reply