In industrial processes and laboratory operations, acidic waste streams are a frequent byproduct—often containing sulfuric acid, hydrochloric acid, nitric acid, or organic acids. These acidic effluents must be neutralized before disposal to meet environmental safety standards and avoid damage to pipes and treatment systems.

A widely used and effective neutralizing agent for such acidic waste is caustic soda flakes (sodium hydroxide – NaOH). With its strong alkalinity, NaOH rapidly adjusts pH, rendering hazardous acids safer for handling and disposal.

Why Caustic Soda Flakes?

- Highly reactive base for fast neutralization

- ≥98% purity, ensuring consistent performance

- Safe for storage and transport in solid form

- Long shelf life, ideal for stockpiling in labs and facilities

- On-demand preparation of neutralizing solutions at precise concentrations

Compared to liquid NaOH, flakes offer greater flexibility in dosing and reduce risks related to chemical handling.

Where It’s Used

Caustic soda flakes are used for acid neutralization in:

- Chemical manufacturing plants

- Pharmaceutical and biotech labs

- Metal finishing and electroplating facilities

- Petrochemical operations

- Educational and research institutions

Whether it’s cleaning acid-contaminated equipment or adjusting effluent pH, NaOH plays a key role in safety and environmental compliance.

How the Neutralization Process Works

- Assessment of Acid Volume and Concentration

pH is measured using sensors or test kits. - Preparation of NaOH Solution

Flakes are dissolved in water to create a 10–30% solution, depending on system requirements. - Slow Addition to Acidic Waste

The solution is added gradually under controlled conditions to avoid heat spikes or splashing. - Monitoring and Adjustment

The pH is carefully monitored and brought to the target level (usually 6.5–8.5 for discharge). - Disposal or Reuse

Neutralized water may be released or further treated depending on contaminants.

Benefits of Using Flakes Over Liquid

- Less corrosion risk in storage tanks

- No chemical degradation during transport

- Precise control in small-batch neutralization

- Lower volume for the same active concentration

- Easier export handling

For international shipments or facilities with limited chemical infrastructure, flakes offer a much safer and more practical solution.

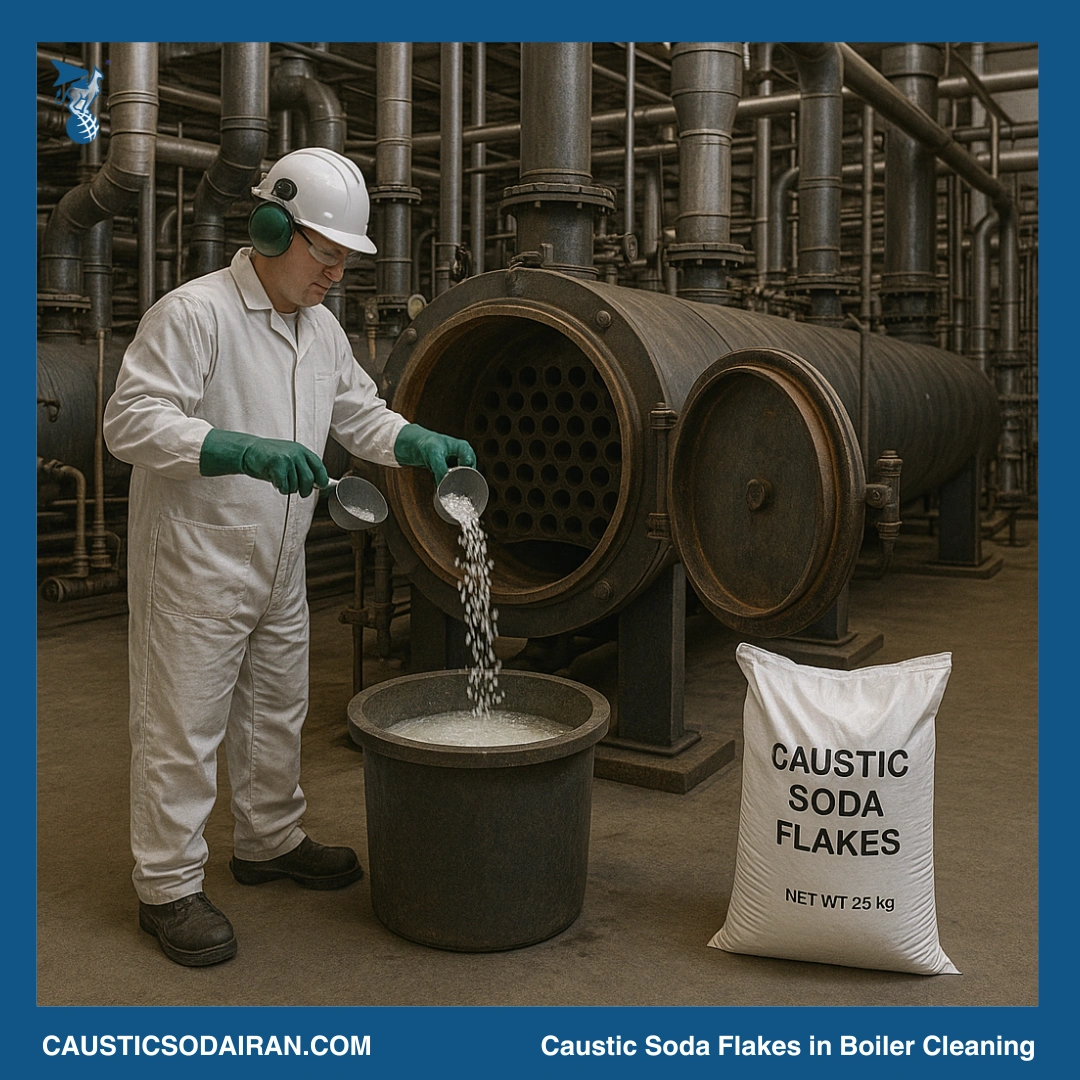

Safety and Handling

Because of the exothermic reaction between NaOH and acid, safety is paramount:

- Always add base to acid slowly (never the reverse)

- Use alkali-resistant containers

- Wear PPE including gloves, goggles, face shield

- Install emergency wash stations near handling zones

- Follow local regulations for waste handling and documentation

Conclusion

Caustic soda flakes provide a safe, efficient, and effective method for neutralizing acidic chemical waste in a wide range of industrial and laboratory settings. Their stability, purity, and strong reactivity make them the neutralizing agent of choice.

Iran Caustic Soda, a division of Shetab Gostar Nadin Trading Co., supplies high-quality NaOH flakes for environmental safety applications with global delivery support.

Leave a Reply