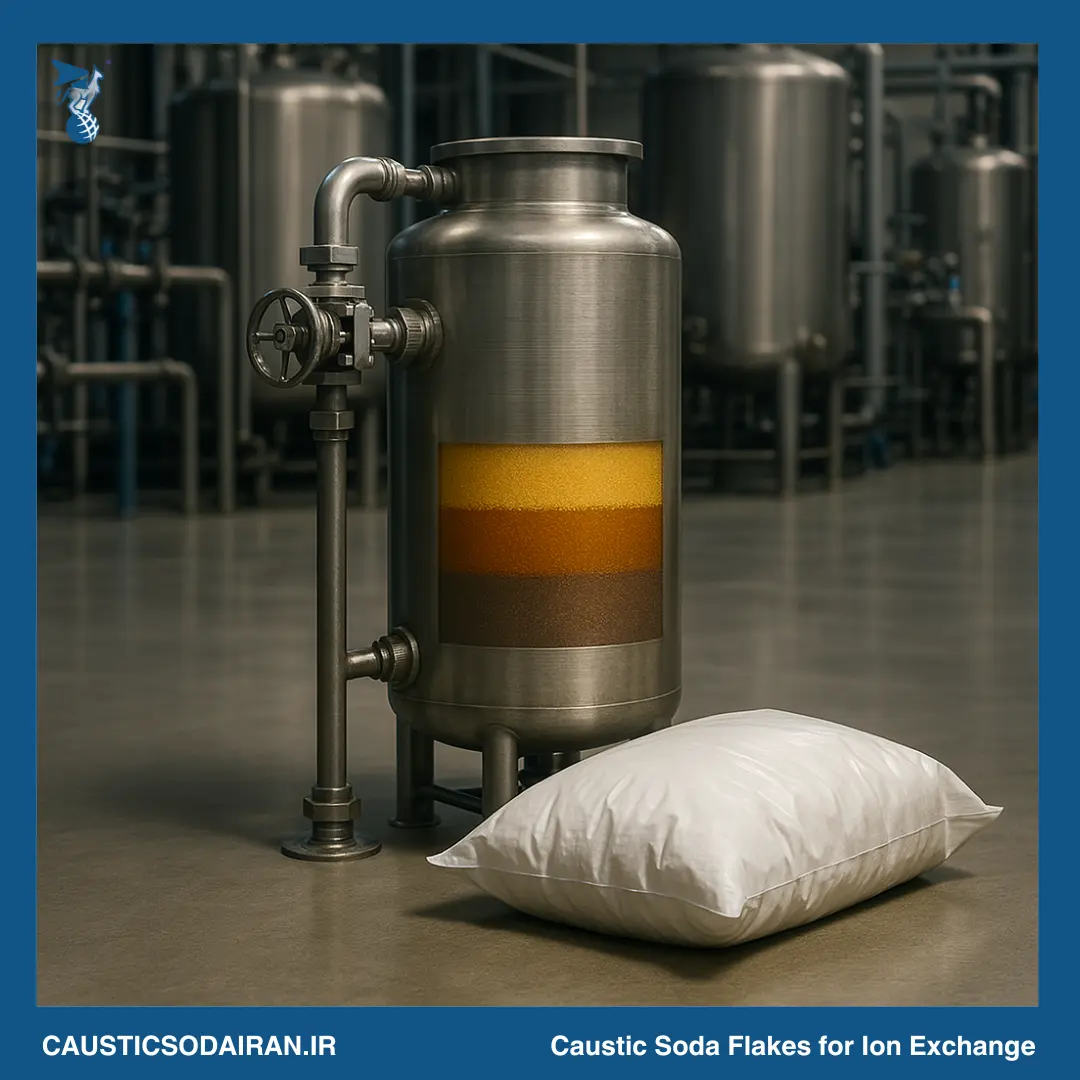

Ion exchange resins are widely used in industrial water treatment systems, including water softening, demineralization, and chemical purification. Over time, these resins become saturated with impurities such as calcium, magnesium, or other ions. To restore their effectiveness, a process called resin regeneration is required—where caustic soda flakes (sodium hydroxide – NaOH) play a crucial role.

Why Use Caustic Soda Flakes in Resin Regeneration?

Caustic soda flakes are an ideal regenerant for anion exchange resins. These resins remove negatively charged ions (such as chloride, sulfate, and nitrate) from water. Over time, they lose their capacity and must be recharged with a strong base—sodium hydroxide.

Using NaOH flakes offers several advantages:

- ≥98% purity, ensuring consistent and effective regeneration

- Long shelf life and ease of storage

- Flexible dosing, as flakes can be dissolved on-site

- Safe transport in moisture-resistant 25 kg or jumbo bags

How the Regeneration Process Works

- Preparation of NaOH Solution:

Caustic soda flakes are dissolved in water to create a solution with the desired concentration (typically 4–10%). - Injection into Resin Bed:

The solution is introduced into the ion exchange column in a controlled manner to displace the attached ions. - Contact Time:

The NaOH solution is allowed to remain in contact with the resin for a specific time to complete regeneration. - Rinse Cycle:

Excess sodium hydroxide and displaced ions are removed by a rinse cycle with clean water.

This process restores the resin’s ability to remove contaminants and ensures optimal performance in the next treatment cycle.

Applications in Industry

Regeneration using caustic soda flakes is common in:

- Water softening systems for boilers

- Power plants and chemical processing plants

- Food and beverage production lines

- Pharmaceutical-grade water purification

Wherever high-purity water is required, NaOH flakes are a standard part of the resin regeneration protocol.

Storage and Handling

Since caustic soda is highly corrosive and hygroscopic, it must be:

- Stored in dry, cool areas, away from acids or moisture

- Handled with PPE including gloves, goggles, and protective clothing

- Mixed in corrosion-resistant tanks or dosing equipment

Refineries and treatment facilities often prefer flakes over liquid NaOH due to their stability during long-term storage.

Conclusion

Caustic soda flakes are a reliable and efficient choice for regenerating ion exchange resins. Their high purity, ease of storage, and strong alkalinity make them ideal for water treatment operations across multiple industries.

Caustic Soda Iran, a subsidiary of Shetab Gostar Nadin Trading Co., supplies high-purity NaOH flakes with full export support and documentation for global industrial use.

Leave a Reply