Industrial boilers are critical to processes in power plants, manufacturing, food production, and chemical industries. Over time, these systems suffer from scale buildup, residual grease, and acidic corrosion—all of which reduce efficiency and lifespan.

To maintain boiler performance, industries use caustic soda flakes (sodium hydroxide – NaOH) as a reliable, cost-effective chemical cleaner. With strong alkalinity and high reactivity, NaOH breaks down contaminants and helps restore system function.

Why Boilers Need Alkaline Cleaning

During operation, boilers accumulate:

- Calcium and magnesium scale (hardness)

- Silica deposits

- Acidic corrosion by-products

- Oil and organic contamination

Left untreated, these deposits cause:

- Reduced heat exchange efficiency

- Higher energy consumption

- Hot spots and metal stress

- Risk of boiler failure

Caustic soda helps solve these problems through alkaline boil-out cleaning and chemical descaling.

How Caustic Soda Flakes Work in Boiler Cleaning

Caustic soda is used in:

1. Alkaline Boil-Out

NaOH solution is circulated through new or fouled boiler systems to:

- Remove oil and grease

- Emulsify organic deposits

- Prepare metal surfaces for passivation

This process is often done before the first operation of a new boiler or after maintenance shutdowns.

2. Scale Removal and Neutralization

When combined with chelating agents or surfactants, caustic soda breaks down:

- Calcium carbonate

- Magnesium hydroxide

- Iron oxides

It also neutralizes acid-based contaminants, restoring chemical balance in the boiler water system.

Benefits of Using Caustic Soda Flakes

- High purity (≥98%) ensures consistent results

- Easy on-site preparation by dissolving in water

- Long shelf life and safe storage in solid form

- Cost-effective for industrial-scale use

- Reduces downtime by restoring heat transfer surfaces

Compared to liquid NaOH, flakes are easier to transport and store, especially in remote or export-oriented facilities.

Application Method of Caustic Soda Flakes in Boiler Cleaning

- Dissolve flakes in water to prepare a 5–10% NaOH solution

- Preheat and circulate the solution through the boiler system

- Hold and soak based on system design (4–12 hours)

- Flush and rinse thoroughly with clean water

- Check pH and restart with clean water or conditioning agents

Always follow manufacturer recommendations or chemical cleaning protocols.

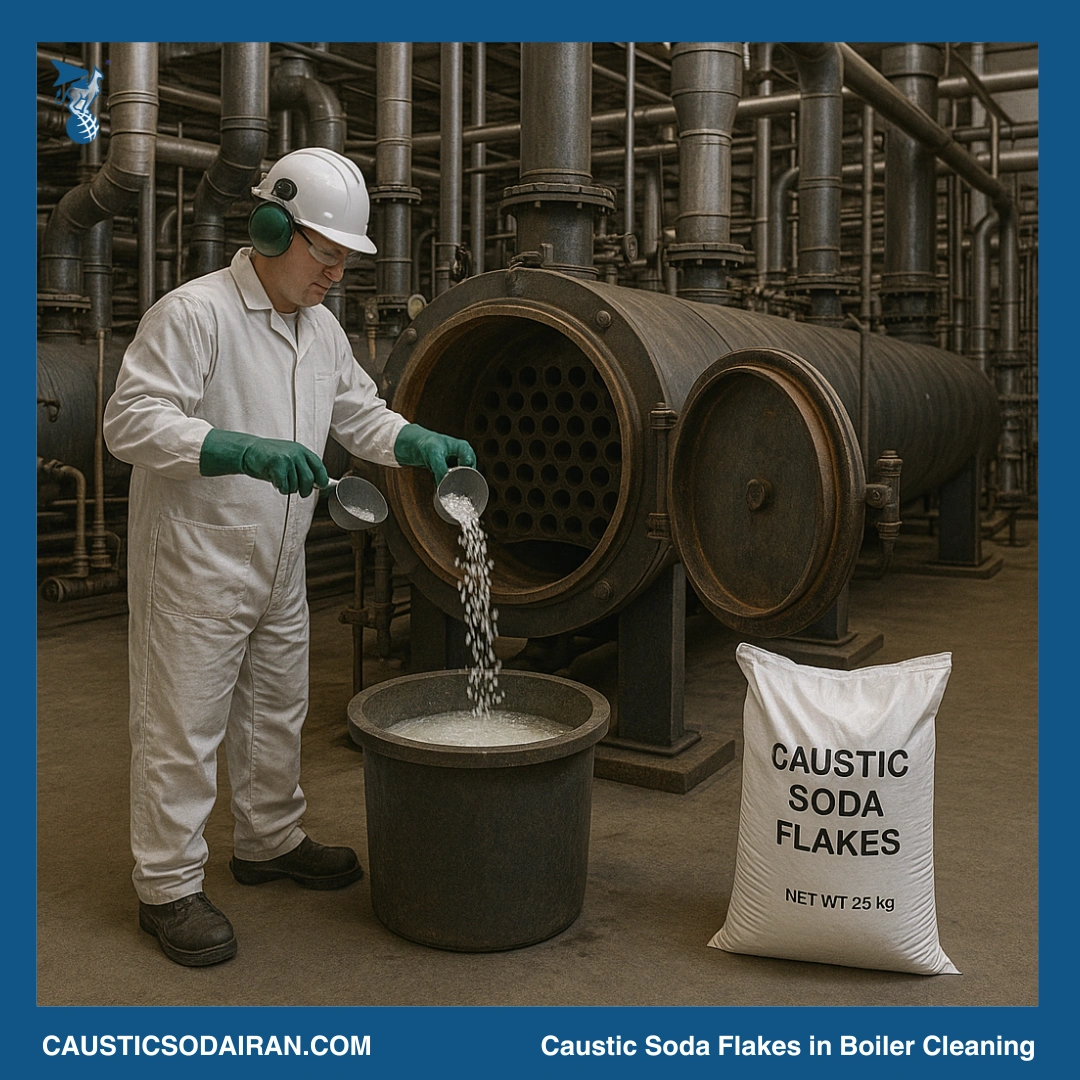

Safety Considerations

Caustic soda is highly corrosive. Safety measures include:

- Full PPE (gloves, goggles, face shield, coveralls)

- Proper ventilation and spill containment

- Neutralizing acid or buffer available on site

- Use of alkaline-resistant pumps and pipes

Spent solution must be treated and neutralized before discharge per environmental guidelines.

Conclusion

Caustic soda flakes offer a practical and powerful solution for cleaning and maintaining industrial boilers. Their strong alkalinity, high purity, and stable storage make them ideal for removing scale, neutralizing acids, and boosting energy efficiency.

Iran Caustic Soda, a division of Shetab Gostar Nadin Trading Co., supplies high-grade NaOH flakes in export-ready packaging, supported by technical guidance and global shipping.

Leave a Reply