In the food and beverage industry, cleanliness is more than just a standard—it’s a regulatory requirement. Equipment in dairy plants, juice processing lines, breweries, and bottled water factories must be regularly cleaned to prevent microbial contamination, product spoilage, and buildup of organic matter.

One of the most effective cleaning agents used in CIP (Clean-In-Place) systems is caustic soda flakes (sodium hydroxide – NaOH). With strong alkalinity and degreasing power, NaOH helps maintain the hygiene of closed piping systems, tanks, pasteurizers, and fillers.

Why Use Caustic Soda Flakes for Food-Grade Cleaning?

- High purity (≥98%) ensures chemical consistency

- Powerful degreasing and saponification action against fat and protein residues

- Removes biofilms, sugar deposits, and scaling from stainless steel surfaces

- Effective against bacteria-harboring residues that cannot be removed by water alone

- Safe for food-grade equipment when properly rinsed

In addition, flakes are easier to store long-term and can be dissolved on-site to prepare tailored NaOH solutions.

How It’s Used in CIP Systems

CIP systems are widely used in closed-loop processing plants. Caustic soda flakes are dissolved to make a 1–2% NaOH solution, which is then:

- Heated to 70–85°C

- Circulated through tanks, piping, pasteurizers, and valves

- Held for a defined contact time to react with residues

- Rinsed thoroughly with clean water to remove all chemical traces

In many systems, acid cleaning (e.g., nitric acid) follows alkaline cleaning for descaling.

Applications in Food and Beverage Industry

Caustic soda flakes are used in:

- Milk and yogurt production lines

- Cheese and whey equipment

- Carbonated beverage bottling

- Juice and concentrate filling systems

- Beer, wine, and kombucha tanks

These cleaning cycles help maintain product safety, equipment longevity, and compliance with food safety standards (e.g., HACCP, ISO 22000).

Advantages Over Liquid NaOH

- Safer storage and transport, especially in hot climates

- Longer shelf life with less degradation

- No spill risk during delivery or warehouse handling

- On-site solution preparation with customized concentration

Many facilities prefer flakes when operating in remote locations or in export-based supply chains.

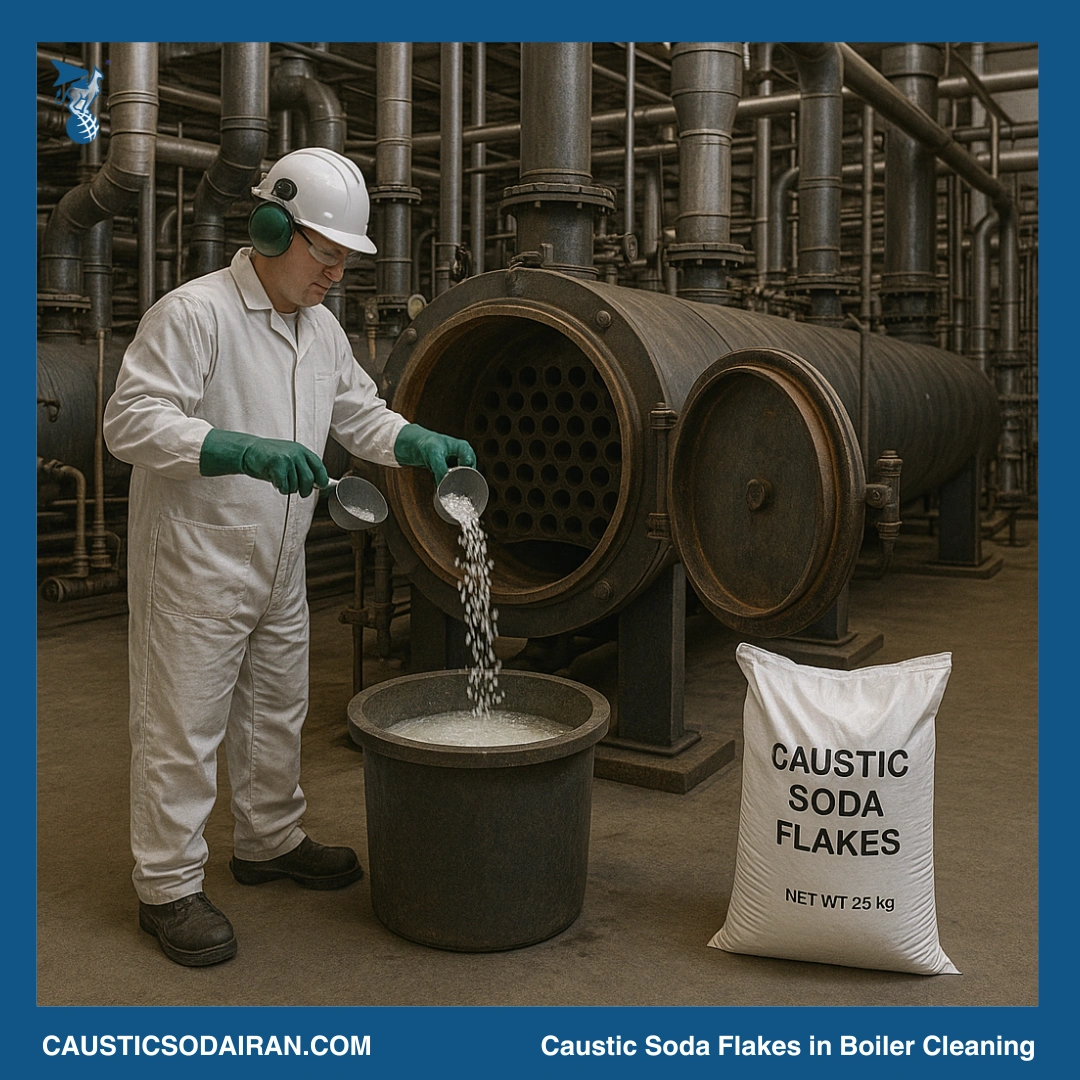

Safety Guidelines

Operators must follow food-grade safety protocols when using NaOH, including:

- Wearing PPE (gloves, goggles, face shield)

- Using alkali-resistant pumps and tanks

- Rinsing all surfaces thoroughly after cleaning

- Monitoring pH of rinse water before resuming production

Conclusion

Caustic soda flakes are a proven and reliable solution for CIP cleaning in the dairy and beverage industry. Their cleaning power, cost-effectiveness, and storage stability make them ideal for food-grade facilities worldwide.

Iran Caustic Soda, under Shetab Gostar Nadin Trading Co., supplies ≥98% purity NaOH flakes in export-ready packaging for hygiene-critical industries.

Leave a Reply