Removing industrial coatings such as paints, varnishes, resins, and chemical sealants from metal or concrete surfaces can be challenging. These coatings are designed to be durable and resistant—but during maintenance, renovation, or reprocessing, they must be stripped effectively.

One of the most efficient and cost-effective chemicals for this task is caustic soda flakes (sodium hydroxide – NaOH). Thanks to its strong alkalinity and reactivity with organic compounds, NaOH breaks down tough polymer bonds and helps restore clean, bare surfaces.

How Caustic Soda Works in Paint Removal

Caustic soda reacts with ester and amide groups found in paint resins and polymers. The alkaline hydrolysis breaks these bonds, causing the coating to:

- Soften and lift from the substrate

- Emulsify into removable residue

- Lose adhesion, making scraping or pressure washing easier

This process is particularly effective for:

- Oil-based paints

- Polyurethane and epoxy coatings

- Bitumen or tar layers

- Enamels and varnishes

Typical Application Areas

Caustic soda flakes are used for paint stripping in:

- Industrial equipment and machinery

- Pipeline and tank exteriors

- Metal parts in fabrication shops

- Ship hull maintenance

- Automotive body shops (pre-treatment)

It is also used in chemical paint stripping baths, where parts are submerged in a hot NaOH solution.

Application Method

- Dissolve caustic soda flakes in water (usually 5–10%)

- Apply hot solution to the surface using brushes, sprayers, or immersion tanks

- Allow contact time (30 minutes to several hours depending on coating)

- Scrub, rinse, or pressure wash the softened coating

- Neutralize surface with weak acid (e.g. vinegar) if needed

For tough coatings, NaOH may be combined with surfactants or organic solvents for enhanced effect.

Benefits Over Solvent-Based Removers

- Non-flammable and safer to handle

- Less toxic fumes than chlorinated or aromatic solvents

- Effective on thick and aged coatings

- Low cost for large-scale cleaning

- Environmentally manageable when used with proper neutralization

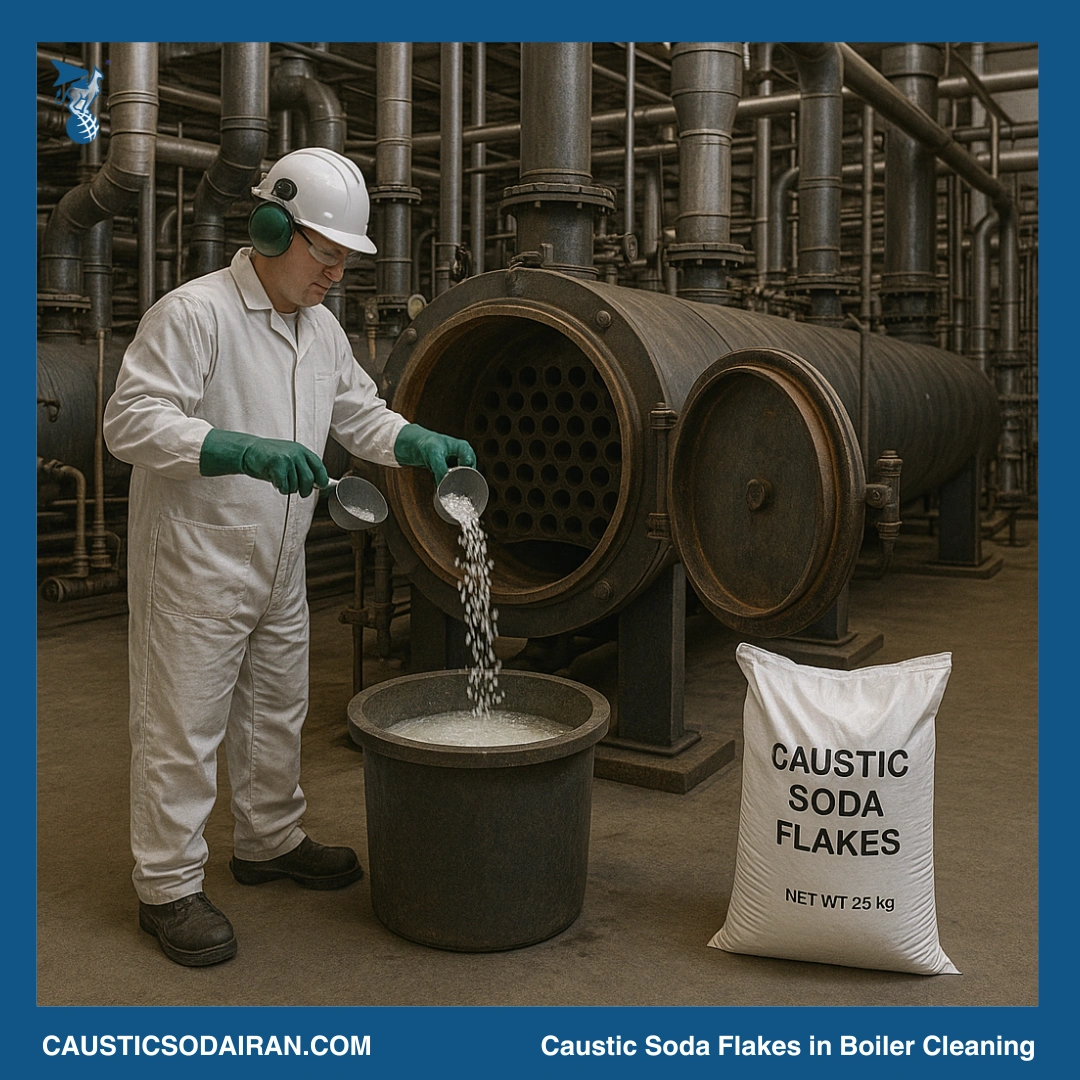

Safety and Handling

Because caustic soda is highly corrosive:

- Always wear PPE: gloves, goggles, face shield, apron

- Use in well-ventilated areas

- Avoid contact with aluminum and soft metals (NaOH is reactive)

- Ensure neutralization and safe disposal of waste solutions

Conclusion

Caustic soda flakes offer an effective, affordable, and industrial-grade solution for removing stubborn paints and coatings from machinery, metal surfaces, and tanks. When handled safely and correctly, NaOH ensures clean results without harsh solvents.

Iran Caustic Soda, a division of Shetab Gostar Nadin Trading Co., supplies high-purity NaOH flakes for industrial cleaning and restoration operations worldwide.

Leave a Reply