Caustic soda flakes (sodium hydroxide – NaOH) are widely used in the oil refining process due to their powerful alkalinity and ability to react with acidic impurities. In both upstream and downstream operations, NaOH plays a key role in improving product quality, protecting equipment, and ensuring environmental compliance.

Acid Neutralization in Crude Oil

One of the primary uses of caustic soda flakes in refining is neutralizing naphthenic acids present in crude oil. These acids can cause corrosion in pipelines and processing units.

Caustic soda reacts with these acids to form sodium salts, which are easier to remove. This process, known as caustic treating, reduces Total Acid Number (TAN) and extends the life of refining equipment.

Desulfurization and Removal of Mercaptans

Crude oil and refined fuels often contain sulfur compounds, such as mercaptans, which contribute to unpleasant odor and increase corrosion risks.

In processes like Merox treatment, caustic soda is used to extract mercaptans from gasoline, kerosene, or LPG. By converting these compounds into sodium mercaptides, the resulting fuel becomes cleaner and more stable.

Caustic Wash of Light Distillates

During the refining of light fractions—such as naphtha, kerosene, and jet fuel—caustic soda flakes are used to remove acidic components and impurities. This ensures the finished product meets international quality standards for odor, pH, and corrosion levels.

The caustic wash process typically includes:

- Mixing NaOH solution with the fuel

- Allowing reaction and separation

- Neutralizing with water wash

- Sending waste to treatment facilities

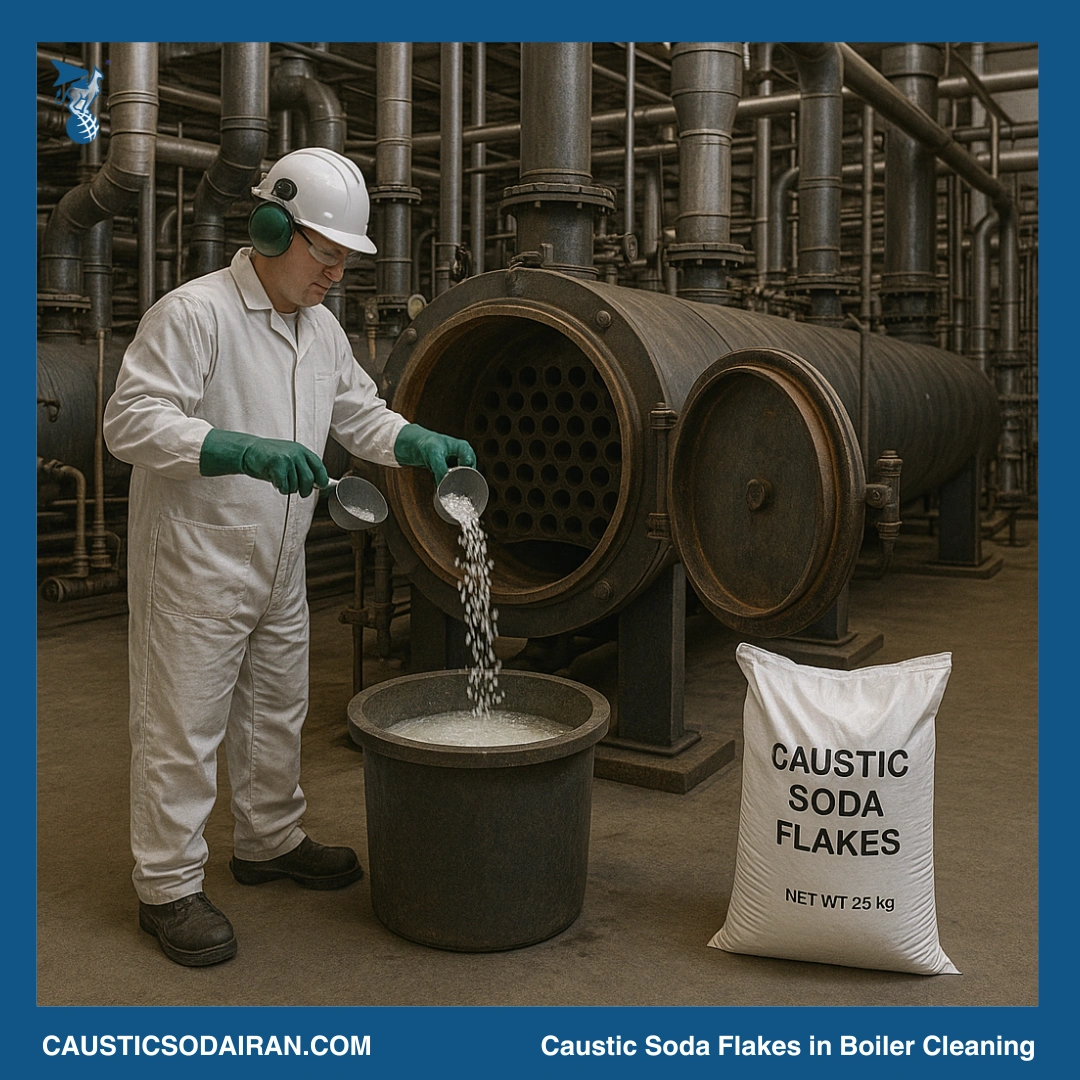

Equipment Cleaning and Maintenance

Caustic soda flakes are also used in cleaning operations within refineries:

- Degreasing pipelines and tanks

- Removing acidic residues from heat exchangers

- Neutralizing chemical spills

Its effectiveness as a strong alkali makes it valuable for maintenance activities that require breaking down organic contaminants.

Safety and Handling

Due to its corrosive nature, caustic soda must be handled with:

- Proper PPE (gloves, goggles, aprons)

- Ventilated storage areas

- Sealed, moisture-resistant packaging

Refineries often purchase flakes in 25 kg PE-lined bags or jumbo bags, and dissolve them on-site to prepare aqueous NaOH solutions.

Conclusion

Caustic soda flakes are indispensable in the oil refining industry. From neutralizing harmful acids to removing sulfur compounds and maintaining plant hygiene, NaOH is a critical chemical for improving fuel quality and extending refinery performance.

Leave a Reply