Aluminum is one of the most widely used metals across industries. The primary source of aluminum is bauxite ore, which contains aluminum hydroxide minerals like gibbsite and boehmite. The industrial method used to extract aluminum oxide (alumina) from bauxite is known as the Bayer process—and the key chemical involved is caustic soda flakes (sodium hydroxide – NaOH).

How the Bayer Process Works

The Bayer process is a two-step chemical extraction technique:

- Digestion (extraction):

Bauxite ore is ground and mixed with a hot, concentrated solution of sodium hydroxide. This dissolves the aluminum-containing minerals, forming soluble sodium aluminate while leaving behind impurities (red mud). - Precipitation and calcination:

The sodium aluminate solution is cooled, and aluminum hydroxide precipitates. It is then filtered, dried, and calcined (heated) to produce pure alumina (Al₂O₃), which is used in aluminum smelting.

Role of Caustic Soda Flakes in the Process

Caustic soda flakes are essential for:

- Breaking down bauxite ore into soluble aluminate

- Maintaining strong alkalinity in the digestion solution

- Reacting selectively with aluminum minerals, leaving iron oxides, titanium, and silicates behind

The effectiveness of this extraction depends on the purity and concentration of the NaOH used.

Why Use Caustic Soda Flakes?

Many aluminum producers prefer solid NaOH flakes over liquid NaOH because:

- Flakes offer ≥98% purity, ensuring efficient mineral breakdown

- They are easy to transport and store in remote mining areas

- They can be dissolved on-site to adjust concentrations as needed

- They are less hazardous during long-distance shipment

In large-scale refineries, flakes are typically stored in bulk silos and fed into digestion units with automated handling systems.

Industrial Efficiency and Yield Improvement

Using high-purity caustic soda flakes:

- Increases alumina yield per ton of bauxite

- Reduces unwanted side reactions with silicates

- Minimizes energy consumption by optimizing dissolution temperature

- Enhances precipitation control and downstream processing

These advantages translate to cost savings and improved production capacity.

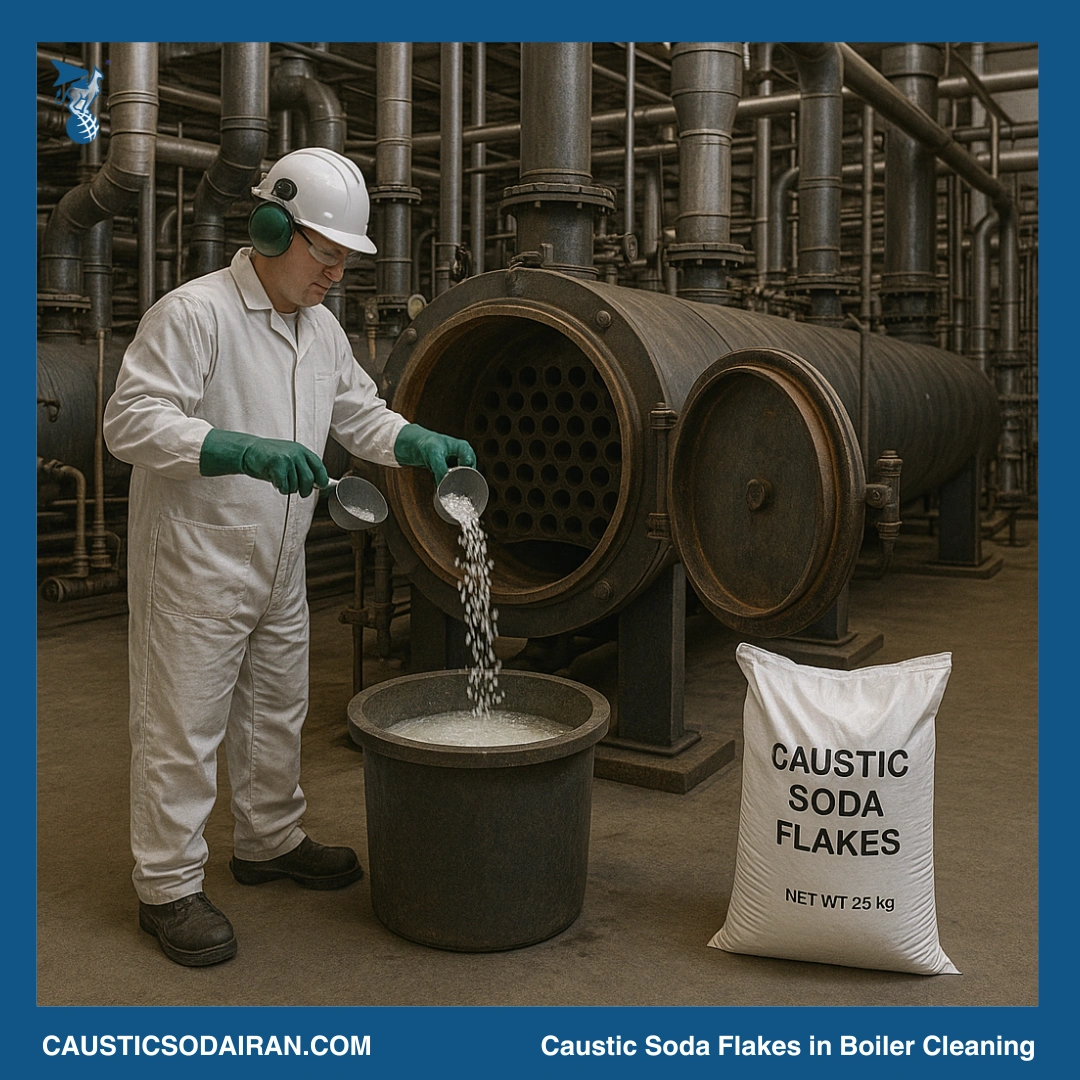

Environmental and Safety Notes

The Bayer process generates red mud, a caustic byproduct. Proper containment, neutralization, and disposal are crucial. Sodium hydroxide must be handled with care using:

- PPE (gloves, goggles, aprons)

- Dust-control systems during flake feeding

- Dedicated alkaline-resistant piping and tanks

Conclusion

Caustic soda flakes are indispensable in the aluminum industry, especially in the Bayer process for extracting alumina from bauxite. Their purity, stability, and industrial efficiency make them the chemical of choice for high-yield refining operations.

Iran Caustic Soda, a trusted exporter under Shetab Gostar Nadin Trading Co., delivers high-purity NaOH flakes for aluminum manufacturers worldwide with tailored logistics and full documentation.

Leave a Reply